dev.a

The Nik & Trick Online dev.a Brochure!

Chemistry

Dev.a supports all development processes currently used in stills photography, we cover both black and white and color and both negatives and positives.

With 6 different chemical tanks at your disposal and 100 programs, even the most demanding processes can be supported. If you’ve always been using a 6-baths E6 kit to develop your precious slides, don’t worry, our machine is here to help.

After the process has ended, chemistry is recovered using the taps on the front of the machine, alternatively, in case of one-shot chemistry, everything can be automatically discarded directly after processing.

All commercially available chemistry can be used, we recommend the made for rotary processing colour chemistry by BelliniFoto and Jobo, each ready as an off the shelf and great value solution using pre-prepared programs so you will be immediately ready to go!

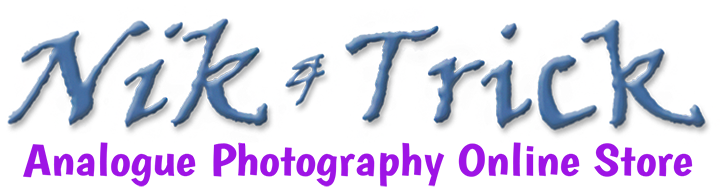

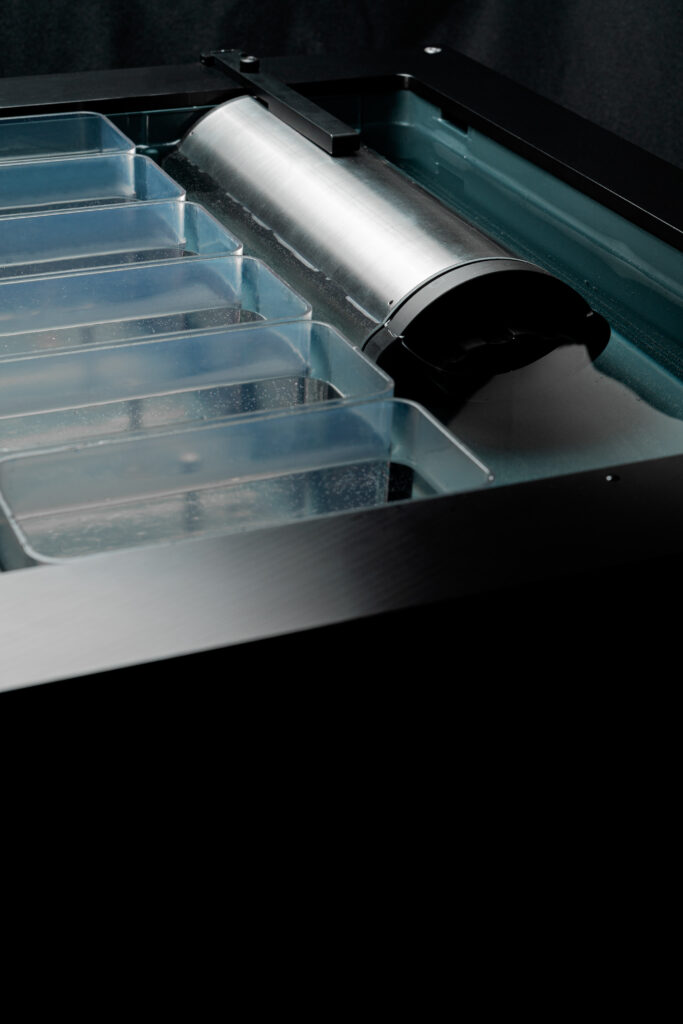

Temperature Control

Maintaining, precise and effective temperature control is extremely important in colour processes such as C41 and E6 but also in general which helps to obtain consistent and reproducible results in any process.

The chemistry tanks and film tanks are fully immersed in a recirculating water bath that heats and tempers both film and chemistry to the desired temperature, which is then consistenytly maintained dev.a throughout the process.

The lastest evolution of dev.a also has much more efficient circulation and heating solutions within the water bath and now warms up faster than ever but maintaining a much more even temperature throughout development…the new machines are fantastic!

The water bath can be filled and managed in two ways:

- Automatically: if the machine is connected to a pressurized water source, such as a sink faucet

- Manually: by pouring the water into the bath from a container

At the end of the working day…It’s a green machine too: Efficiently managing water to prevent wastage. Flushing between process stages using only what is required and then cleansing itself using the water from the tempering bath when finished.

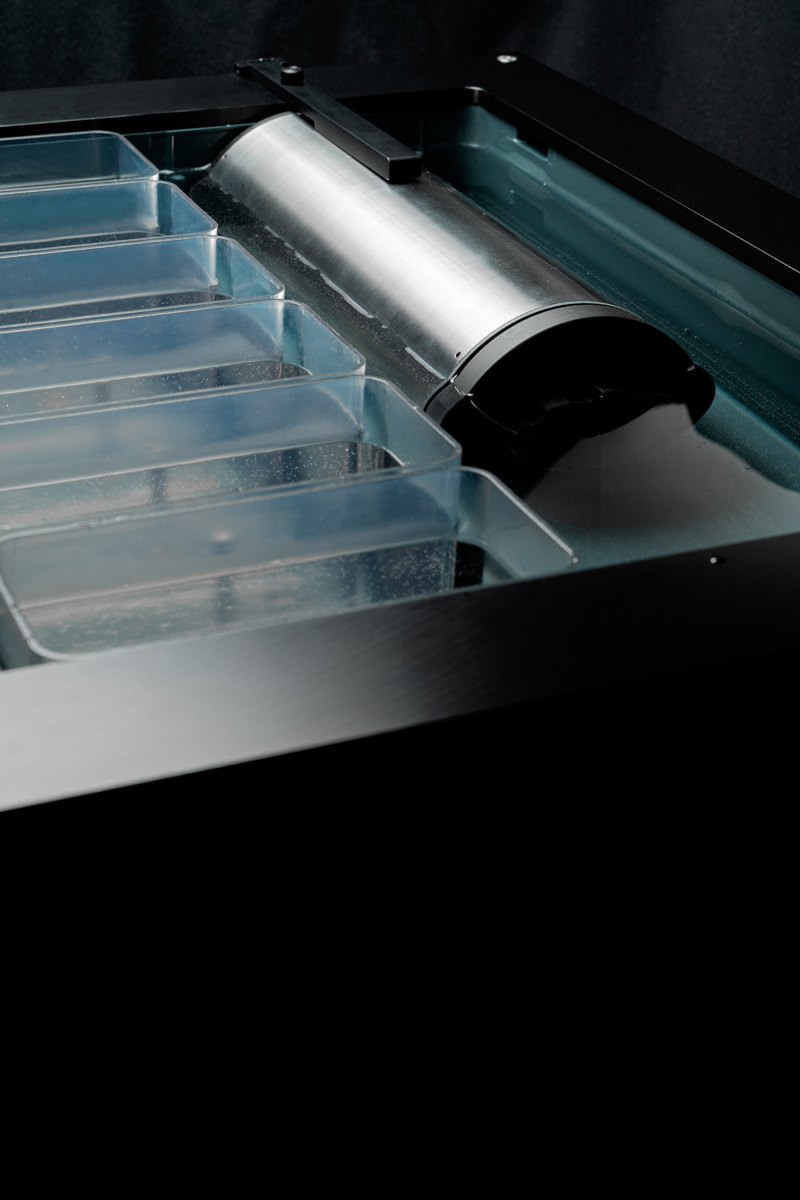

Film Tanks

To make life easy, Dev.a tanks are engineered to accept the most readily available reels by Paterson/AP and Jobo.

For 110/16mm, 35mm or 120 rolls, tanks are compatible with Jobo series 1500 reels or with Paterson/AP reels. For large format processing we custom reels are available.

A trio of three different tank sizes are offered in order to suit your processing needs. The following table lists film capacity and required chemistry for each tank

Naturally, the variety of film format combinations in same tank are pretty diverse…from the 16mm Jobo to the dev.a 10×8 & 5×4 units…which are also now available

dev.a agitates using the rotation method which is provided by newly developed cog drive mechanism built into the base and inner column of the tank. When the motor turns, the film turns as well a very effective and efficient mechanicl deveice.

Rotation parameters, such as speed and inversion interval, once again are fully customisable and can be configured to your preference via the User Interface.

Three tank sizes are available, the following brief guide showing capacities…not mentioned are 16mm Jobo 1500 spirals or the forthcoming solution for large format sheet films in the largest tank.

Also, remember that by reclaiming and re-using chemistry you are still dealing with the same depletion rates as you always were!

Uses 650ml Chemistry accepting 2x 35mm or a single 120 real

Requires 850ml of chemical and accepts 4x 35mm or 2x 120 reels

Takes one litre of chemistry covering 6x 35mm or 3x 120 or combination of….will later also accommodate sheet films up to 10×8

User Interface

This is the best bit…the user interface is smiply brilliant!!

Controlled using it’s unique new software, an intuitive user interface via the large 7″ touch screen, operating dev.a is as easy as using an app on your phone, perhaps even easier in fact!

Several common processed are pre-installed, those like all 100 programs are fully customisable. Even if some processes are standard it’s often desirable to be able to tweak them to suit your own needs or preferences which makes this machine just about the most versatile film processor in todays market.

dev.a makes no interruption to any other work needing doing in your darkroom. All illumination for the machine, the display and the status led can be turned completely off without shutting the machine down, dev.a will just carry on processing film in the background without risk of any light contamination whatsoever.

The display itself is mounted on a hinged plate which can swivel in and out. When not in use the screen folds away safe from harm, flat against the machine body.

Process settings can be exported to to a USB drive to create a backup of your data. That backup can be imported if ever needed or shared with another machine without having to enter everything again from scratch.

Impressed yet?

You should be….this is potentially the most important new bit of professional darkroom hardware in three decades.

Now we have ours we can assure you that it is beautifully engineered, build quality is outstanding as is the thoughtful design that emphasises the Italian flare for such things….this is the Lamborghini of processing machines!

So, lets take a closer look…..

Get a better feel for this beautiful machine in the gallery below…

Special Introductory Price Until 2022

Orders will require a 50% deposit in order to secure a dev.a ~ Carriage costs at buyers expense of course and may vary according to location, we shall work hard to make this as secure and efficient as possible.

Get in touch to order, follow us on Facebook or Instagram @nikandtrickphotoservices and follow our own experiences with this all new machine

..and finally a few words from the inventor about dev.a

Regarding the history of this product we go back just a couple years!

My name is Andrea, dev.a was my idea, my invention and here is how it came about:

I’ve been interested/passionate about film photography for about a decade and in this period I’ve almost always been doing my own film development as well as my own darkroom printing (regularly in the past 5-6 years).

About two or three years ago I had the idea of designing a completely automatic film processor…

At first the idea was to develop my own film without the hassle of temperature control, agitation, pouring chemistry, etc. but then, one day, I brought up the idea at work and we realized that, given the lack of alternatives, the recent increases in interest for film and film photography we saw that there could be a potential market for this kind of machine.

Like any new technological product development it’s difficult to justify such a huge investment of time and money just for myself and my random holiday photos! It had to be a marketable product.

By profession I’m a software engineer, I also dabble in electronics if necessary…in the beginning film photography was only a passion of mine and then we started this project but now it’s also part of my job!

For the past few years I’ve been working in the family company, to my surprise, it hasn’t been difficult to convince the management (my father) to go on with this project.

The company itself is a family business, one that has been working for over 20 years on the manufacture of ticketing and access control machines.

Engineering and manufacture of such equipment endowed us with all the professional and technical skills, mechanical, electronic, electro-mechanical, software and so on, all of the engineering capability to make dev.a into a working modern product.

Thank you so much for considering dev.a

Andrea